没知识还要咄咄逼人真是可怕,要较真就较真到底,看这个: vulcan_on_ice2011-09-07 07:09:50

Meat Safety:Temperature Control

Storing and processing the freshest meat at low temperatures is the strongest weapon that we have to fight bacteria. Additional factors such as adding salt, nitrite, increasing meat's acidity, eliminating moisture, vacuum packing and others are additional safety measures that help to produce a safe product with the maximum shelf life. Nevertheless the single most important factor is using the lowest practical temperatures for processing and storing meat. When you answer the telephone and leave ground meat on the kitchen table for 3 hours it will not matter much, as long as you only make one or two pounds of sausage. It will be consummed in a day or two and there will not be enough time for the meat to go bad. But if you buy a 50 lbs box of pork butts to make different sausages for your family at Christmas, now it is a different matter. You can not eat all that meat in a day or two. Some of it will hang in the kitchen, some will be in a refrigerator, a good half will go into the freezer. It is in your own interest to have those sausages last as long as possible and now all those low temperatures and good manufacturing techniques will come into play.

Effects of Time and Temperature on Bacteria Growth

Under the correct conditions, spoilage bacteria reproduce rapidly and the populations can grow very large. Temperature and time are the factors that affect bacterial growth the most. Below 45° F bacteria grow slowly and at temperatures above 140° F they start to die. In the so called “danger zone” between 40-140° F (4-60° C) many bacteria grow very well. Most bacteria will grow exponentially at temperatures between 70° F and 120° F. When bacteria grow, they increase in numbers, not in size. Let’s see how fast bacteria grow at ideal temperature:

| Number of bacteria | Elapsed time |

|---|---|

| 10 | 0 |

| 20 | 20 minutes |

| 40 | 40 minutes |

| 80 | 1 hour |

| 160 | 1 hour 20 min |

| 320 | 1 hour 40 min |

| 640 | 2 hours |

| 1280 | 2 hours 20 min |

| 2560 | 2 hours 40 min |

| 5120 | 3 hrs |

| 10,240 | 3 hrs 20 min |

| 20,480 | 3 hrs 40 min |

| 40,960 | 4 hrs |

| 81,920 | 4 hrs 20 min |

| 163,840 | 4 hrs 40 min |

| 327,680 | 5 hrs |

| 655,360 | 5 hrs 20 min |

| 1,310,720 | 5 hrs 40 min |

| 2,621,440 | 6 hrs |

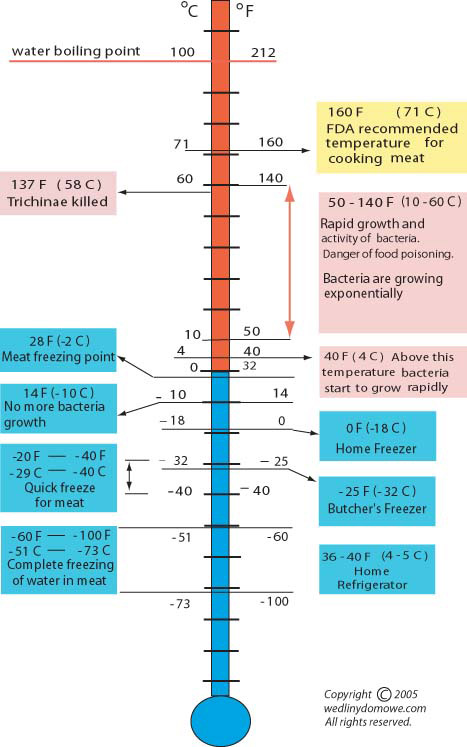

Now it becomes evident what happens to a piece of meat left out on the kitchen table for many hours on a beautiful and hot summer day. The thermometer drawing that follows below has been compiled from the data we found at the College of Agriculture, Auburn University, Alabama. It shows the time that is required for one bacteria cell to become two at different storage temperatures. Looking at the drawing we can see that once the temperature rises above 50° F (10° C), bacteria will double up every time we raise the temperature by about 5° F. From the above examples we can draw a logical conclusion that if we want to process meats we should perform these tasks at temperatures not higher than 50° F (10° C). And those are the temperatures present in meat processing plants. You might say that lowering the temperature of the room will be better still. Of course it will be better, but people working in such conditions for 8 hours a day will find it very uncomfortable.

|

It can be seen that at 32° F (0° C) bacteria needs as much as 38 hours to divide in two. That also means that if our piece of meat had a certain amount of bacteria on its surface, after 38 hours of lying in a refrigerator the amount of bacteria in the same piece of meat will double. If we move this meat from the refrigerator to a room having a temperature of 80° F (26.5° C) the bacteria will double up every hour (12 times faster). At 90° F (32° C) they will be dividing every 30 minutes. Bacteria growth with temperature. |

|---|

After cooking, meats are free of bacteria, but leaving them warm for an extended time will invite new bacteria to settle in and start growing. For this reason smoked and subsequently cooked meats are submitted to cold showers to pass through the “danger zone” as fast as possible.